Transforming the future of production

Why KELENN Technology?

Towards industry 4.0

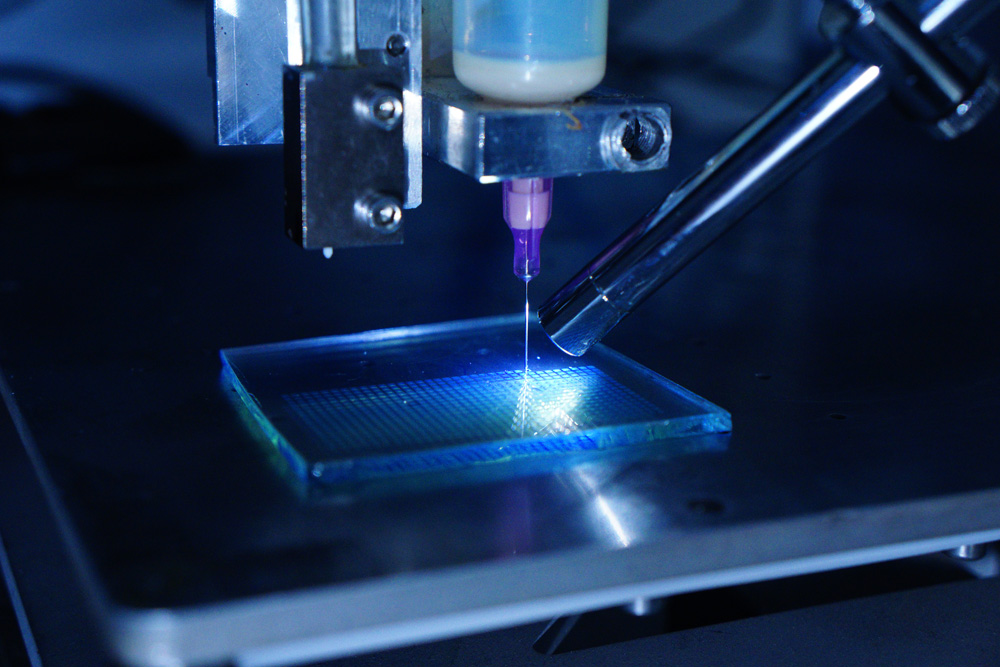

Since 2005, we have been investing heavily in research and development of technologies, enabling us to deliver increasingly innovative solutions. Our modular and robust machines are tailored for Industry 4.0, specializing in electronic printing, automated vision, inkjet printing, and supervisory software.

The development of innovative technologies focused on the environment and society is paramount to us. We focus on specific areas, committing to design machines and solutions that will enable our clients to reduce their embodied energy.

A proven technology

KELENN has completed over 200 projects specifically tailored to our clients, in various fields such as of research, publishing, aerospace, automotive, defense or medical.

We are attentive to the current manufacturing challenges faced by our clients, and we support them by providing turnkey solutions that are easy to use.

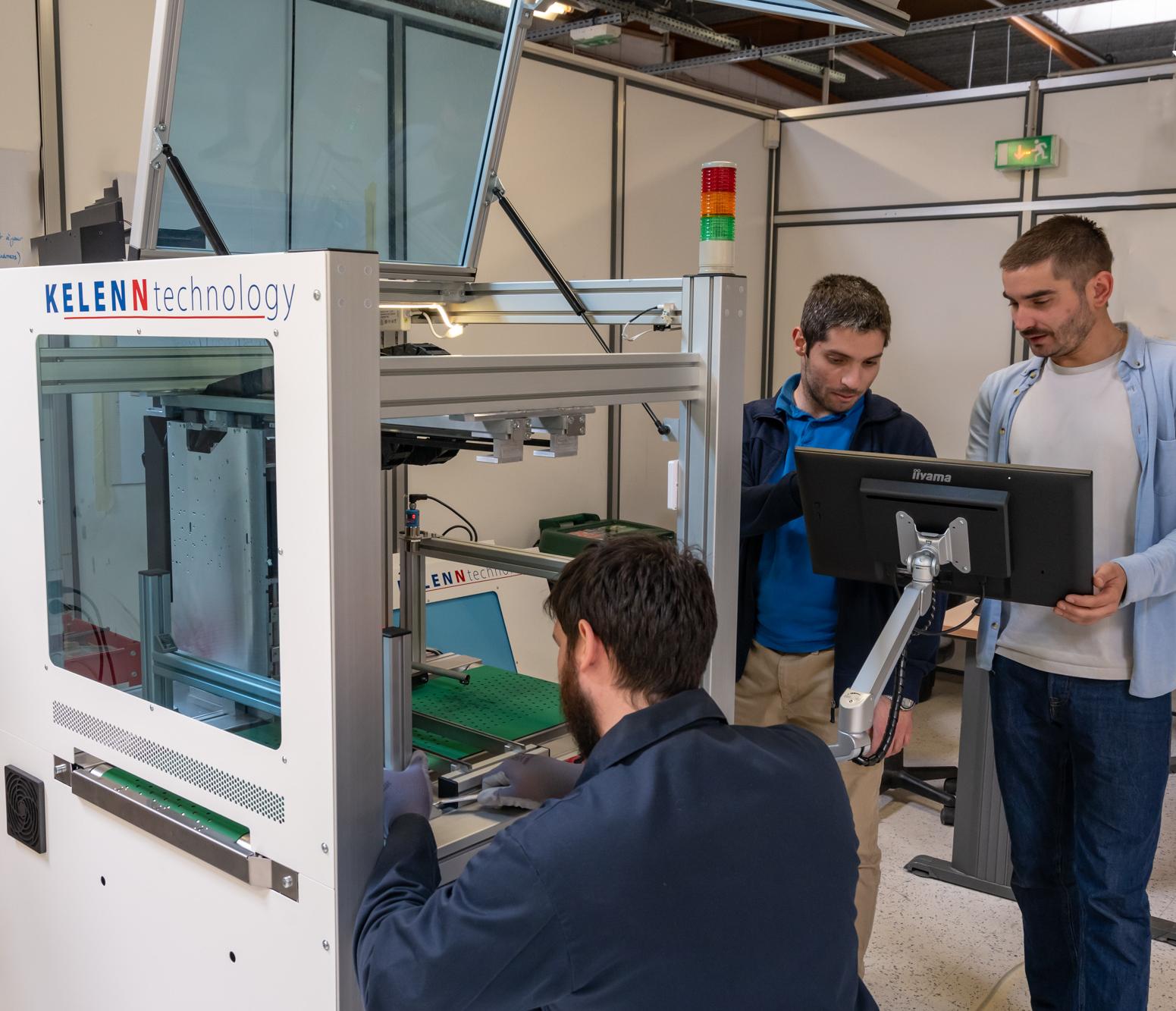

An experienced and passionate team

Composed of developers, engineers, and professionals with multidisciplinary skills, our team members are distributed across four engineering departments: Electronics, Mechanics, Materials, and Software.

Each member brings their own expertise and passion for innovation, working together in a stimulating environment to tackle the most complex technological challenges

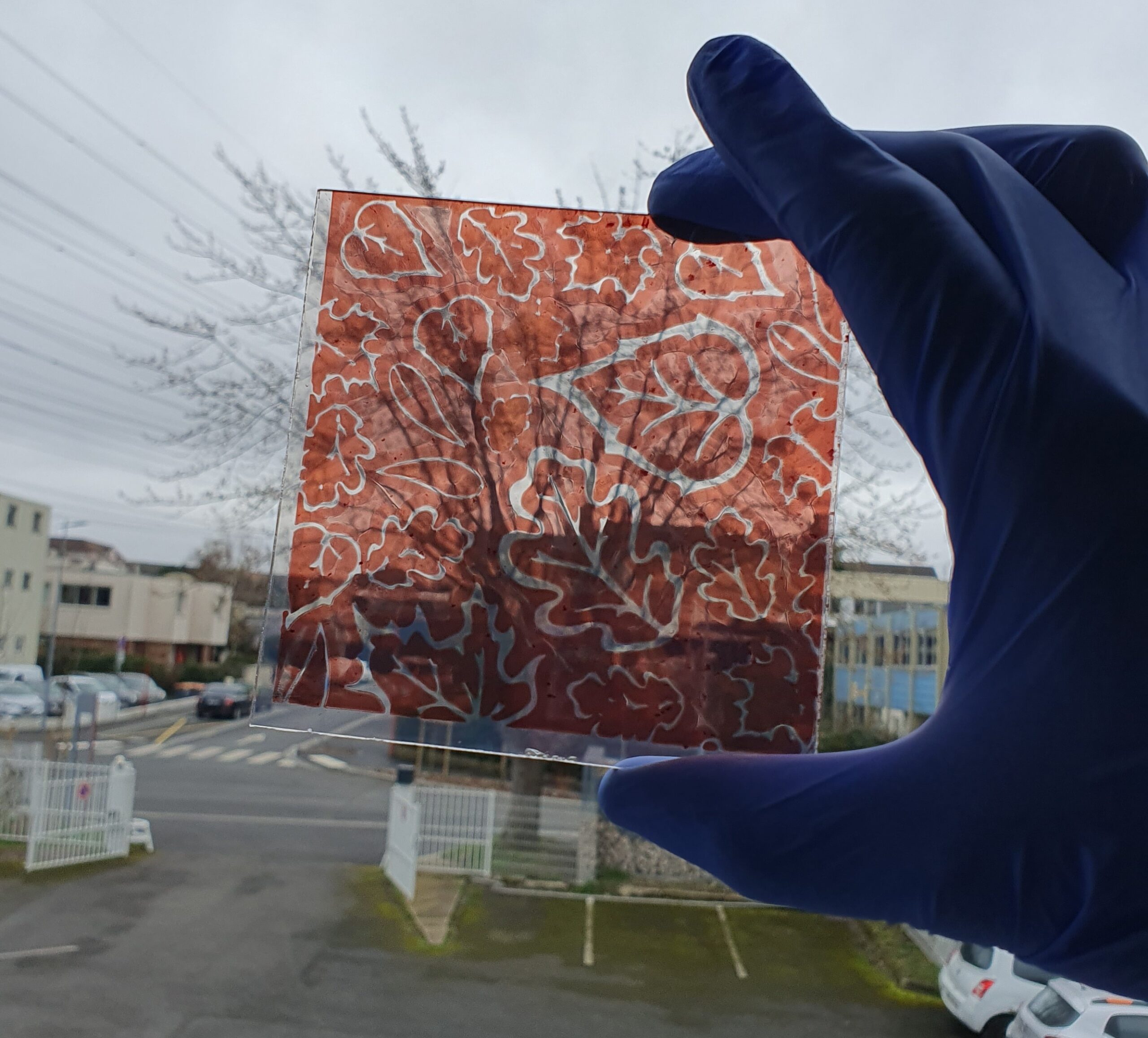

KT Labs

KT's research laboratory plays a fundamental role in creating innovative printed electronics processes developed within the company.

Our research activities include the development of new processes, as well as collaborative research and development with our clients. We also engage in academic research, with a series of publications in various fields such as materials, photovoltaic cells, and batteries.

KT Labs has invested 15 million euros from our own funds, resulting in several patents.

Sustainable innovation

We are embracing a new model where our machines enable demand-driven production: the focus is no longer on large-scale production from a distance, but rather on local production based on needs, through customization and Industry 4.0.

KELENN is dedicated to developing innovative technologies that reduce our carbon footprint and minimize the environmental impacts of our productions. To achieve this, we adopt the 6R method, which involves Reducing waste, the number of parts, operating costs, transportation, subcontracting, and Reusing materials as much as possible.

Our vision

Serving our customers

Advancing science and technology

Enriching knowledge