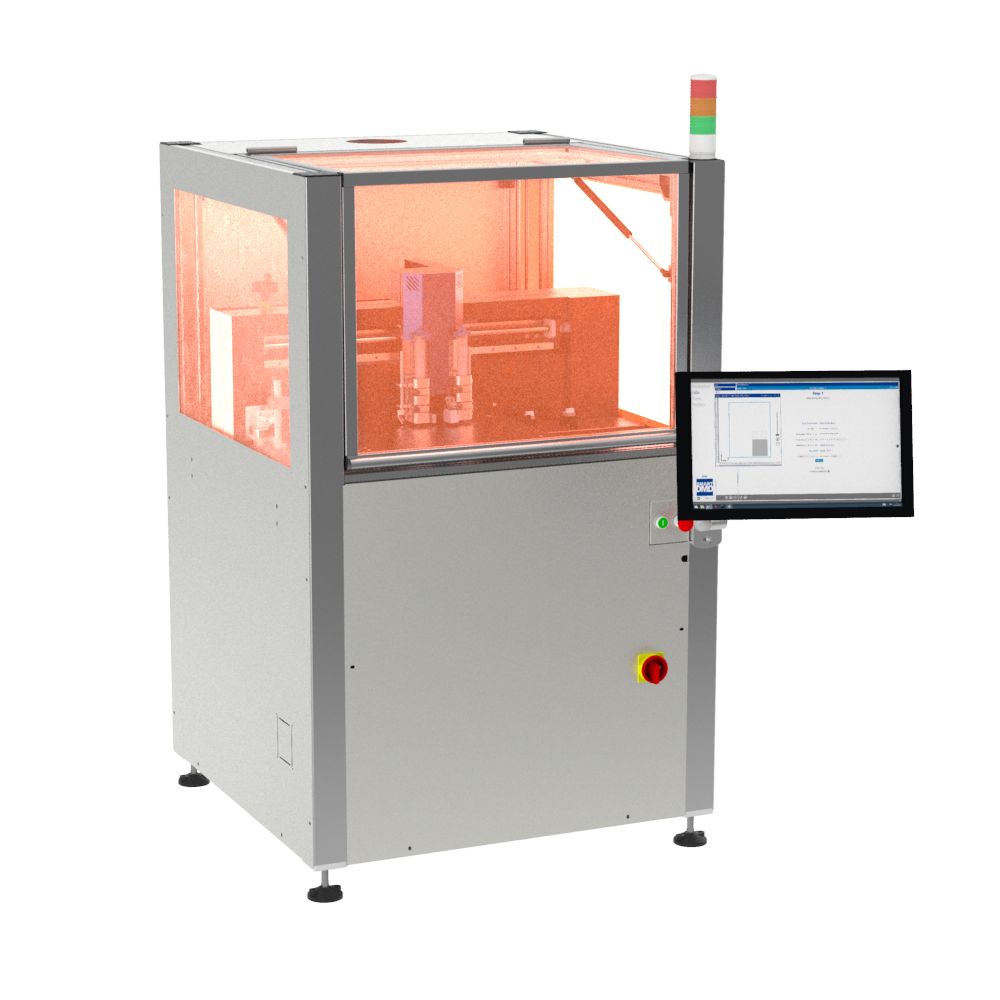

DMD400

Functional material printer for all viscosities for printed electronics

Your laboratory and printed electronics workshop in a single machine

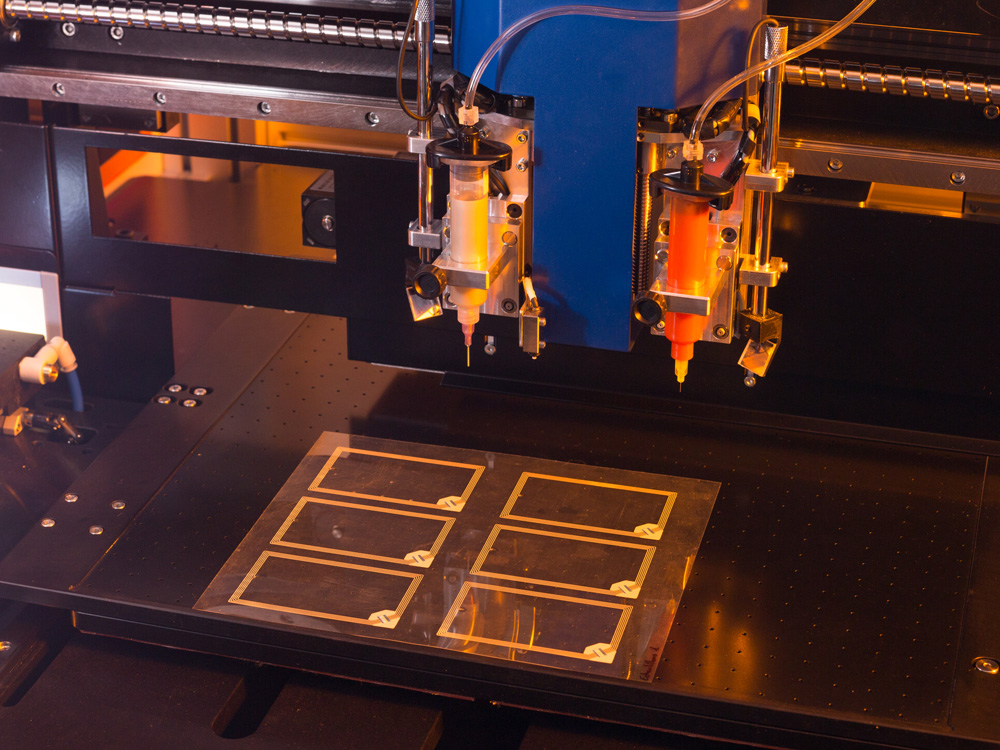

Print and test your new functional materials in minutes directly from the CAD file, without having to adapt your inks to the constraints of inkjet heads.

Design your 3D multilayer designs, print them, automatically place and connect your electronic components, including bare chips.

More than a printer

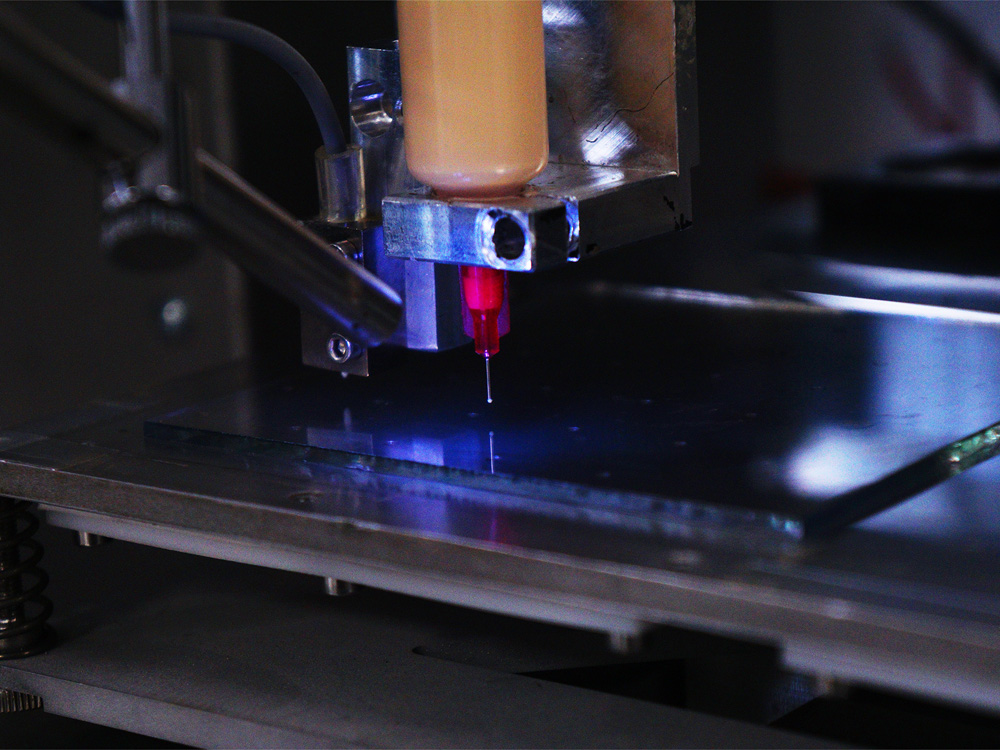

Master the thickness and width of printed tracks regardless of the materials, their viscosity, and particle size. Tools are available to:

- Measure the surface tensions of the selected materials

- Measure and display your prints in 3D layer by layer as well as your placed components

- Visualize your productions with a camera

Increase your productivity with the innovative Smart DMD software. Freely print complex multilayer designs on flat surfaces and simple 3D volumes, set and qualify your deposits, align your layers, program the sintering of materials, automatically place and solder your electronic chips, save and reuse your setups for your productions…

Digital printing reimagined

With only 0.5 ml of ink loaded into a cartridge, start printing to test your new formulation, or fill 10 ml in your cartridge and reuse it for each new implementation.

The ink cartridges and capillaries are interchangeable; multiple diameters and characteristics are available at low cost to the user.

Freely create or purchase your inks, as well as other consumables!

Speed and reliability

Start your tasks and come back when they’re finished!

With a multitude of innovative tools integrated and intelligent management of ink deposition and electronic component placement, we have simplified complex processes to make this machine easy to use.

Applications

Printed electronics

Tags, RFID, bluetooth

Batteries, photovoltaic cells

Biosensors, IoTs

Interconnected electronic systems

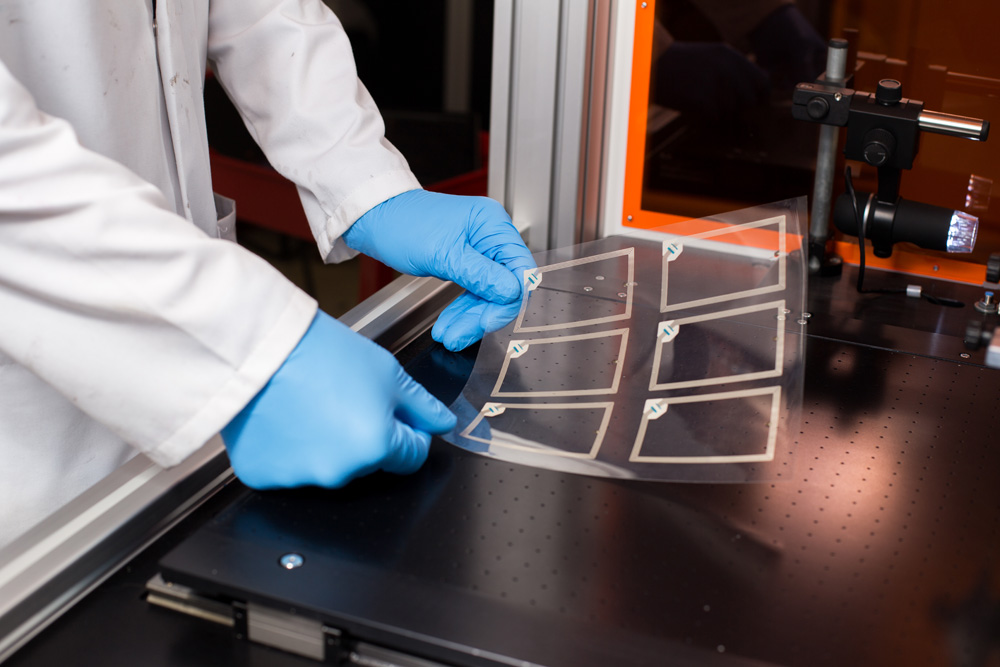

Electronics on fabric and stretchable materials, flex

2D/3D Plastronics, printed circuit

Activities

Prototyping

Small-scale productions

Development of new processes or designs for high-volume printing sectors in digital or analog, such as screen printing

Evaluation of interactions between materials and substrates

Design of functional materials

Industry - Biology

Additive deposits, biological and chemical

3D printing of hybrid systems

Technical specifications

Dimensions

L 1000 mm x L 1000 m x H 1600mm

User Interface

Operator computer with 23″ touchscreen on a mobile arm

Equipments

Digital deposition devices for materials and electronic components, goniometer, inspection and positioning by cameras, thermal post-treatment and UV curing, topography sensor, HEPA filter, heating plate…

Software

Design and management of 3D printing with multiple layers, multi-materials, and multi-tools, component placement and connection, drop angle measurement, production configuration management

Viscosity

Viscosity range from 1 cps to 80,000 cps

Particle size

Up to 100 µm

Deposits

Flat surfaces of 400×400 mm or on 3D objects up to 40 mm in height