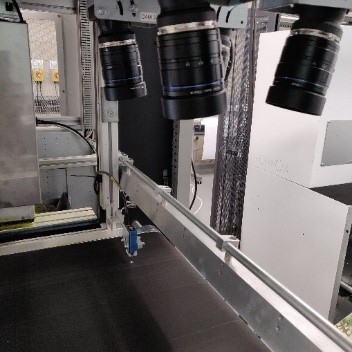

DPP320-R

CMS and bare die chips assembly line on flexible substrates

Continuous assembly of electronic components on flex substrates

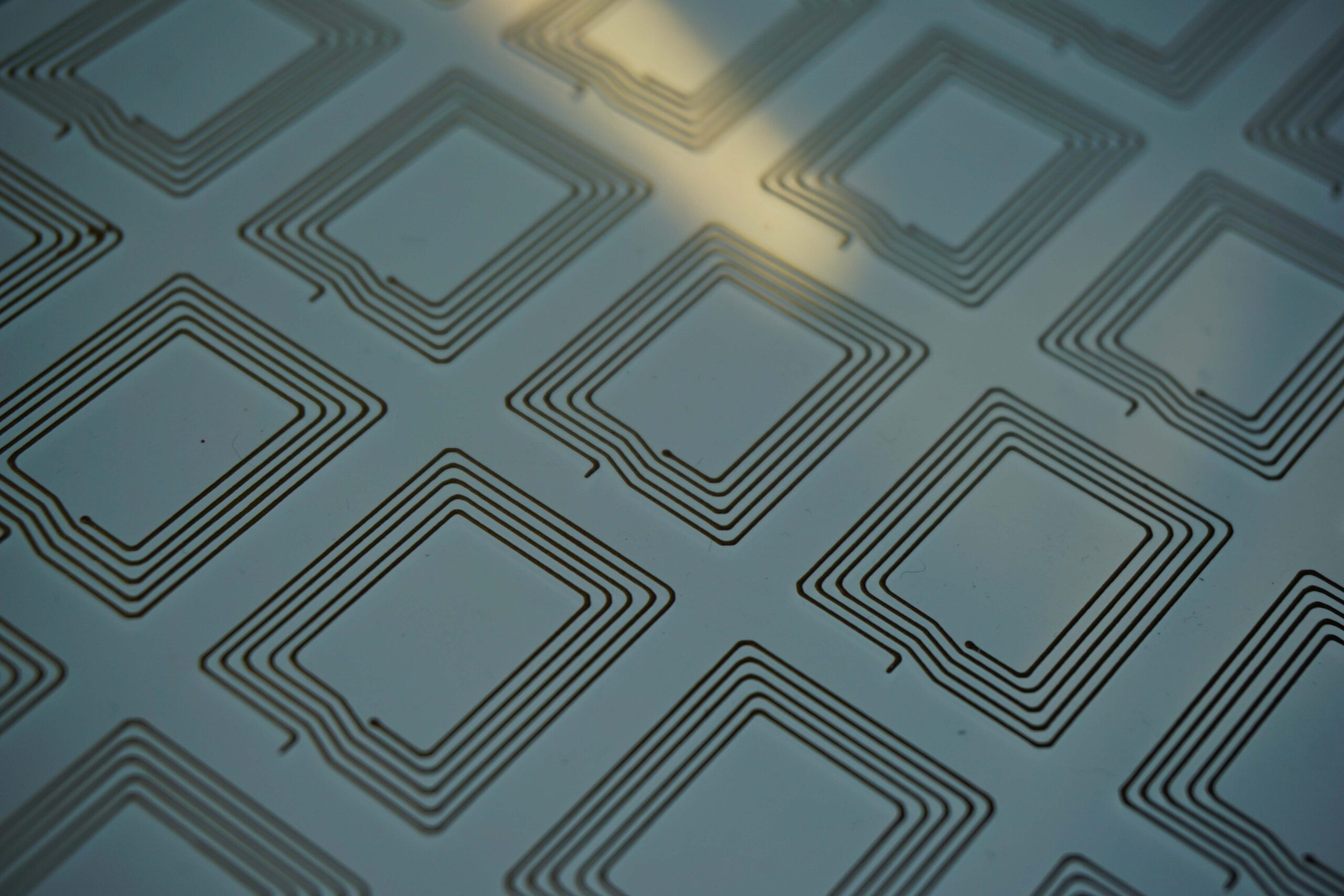

Roll to roll assembly enables mass production of IoT devices such as RFID tags, medical devices and traceability devices for logistics or for food industries.

The DPP320-R performs numerous functions on roll-to-roll substrates:

- Glue patterning, protective conformal selective coating, and globe-top

- CMS components or bare die chips assembly

- Chip programming via electrical radio connexion

- Component testing, typically via UHF RFID, NFC, or Bluetooth transmission

- Conductive tracks printing

Here are some of the benefits of continuous assembly of electronic components on flex substrates:

- High efficiency: The continuous assembly process can be used to assemble a large number of components in a short amount of time.

- Cost-effective: The continuous assembly process is a relatively low-cost manufacturing method.

- Flexibility: The continuous assembly process can be used to assemble a wide variety of components.

- Quality: The continuous assembly process can produce high-quality electronic devices.

Secure your productions

The DPP320R is full featured:

- Track-and-Trace, automatic inspection cameras, product serialization

- Automated process of input production request and output production audits

- Dynamic marking of productions

For added value in electronic circuits production

Combine the DPP320R production lines with HFOne for printing in house functional electronic circuits.

Technical specifications

Production rate

From 2 500 to 15 000 p&p per hour

Substrates

Polymide, PET, FR4, Paper, flat, carton…