DPP320-S

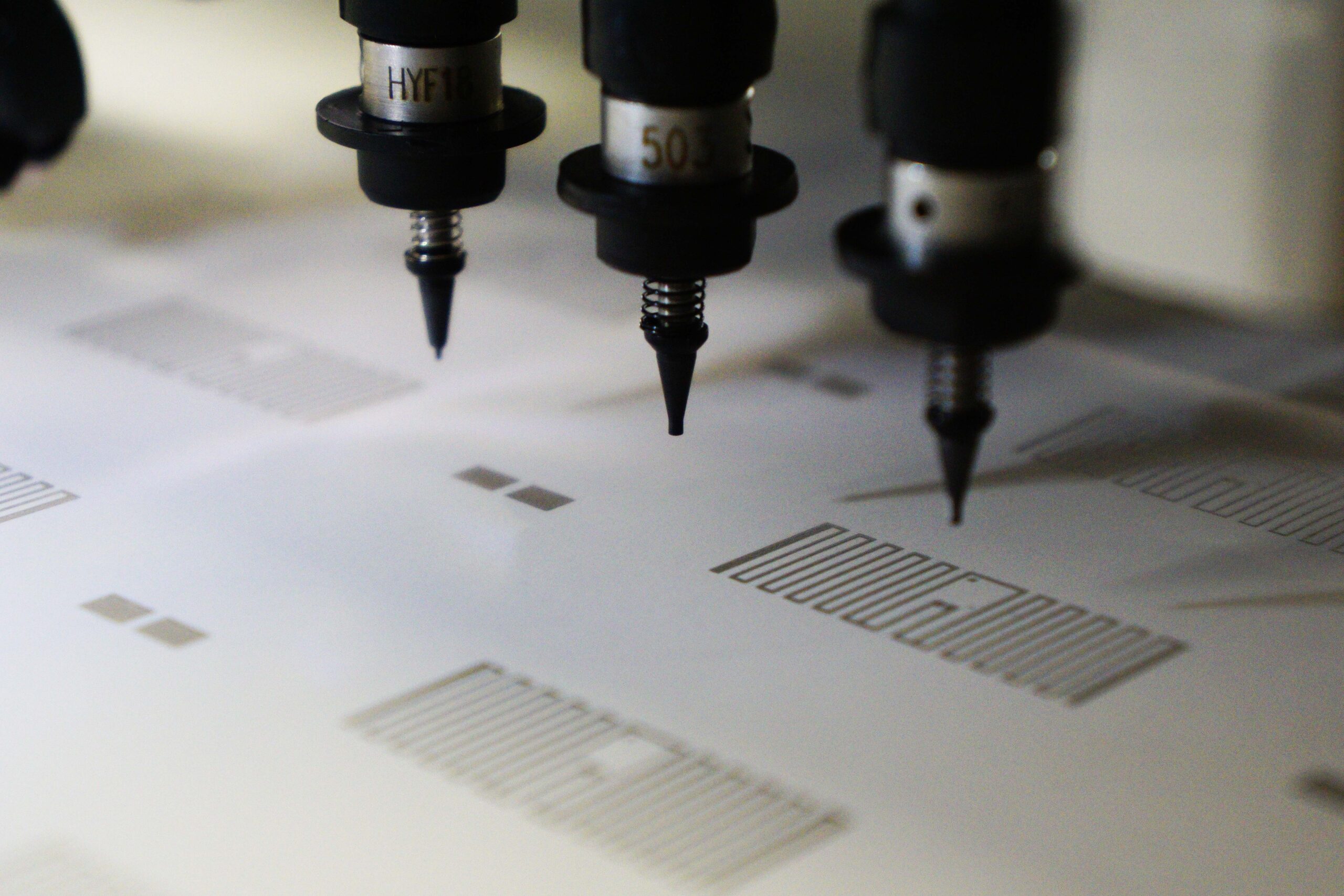

CMS assembly line and bare chips on flexible substrates

Assemble your components on flexible substrates sheet by sheet

The DPP320-S offers great production flexibility for series ranging from 1 to 1000 sheets per day.

The DPP320-S is available in configurations with 1 or multiple modules assembled in series, allowing you to customize your production line:

- Adhesive deposition, selective varnishing, globe-top application

- Assembly of CMS components or bare chips

- Component programming via electrical contact or radio

- Component testing, utilizing UHF RFID, NFC, Bluetooth transmission

- Component protection with selective conformal coating

- Printing of functional traces

Choose your substrate

Assemble your components for your small or medium-sized production runs on various types of flexible substrates!

Equipped with a sheet feeder and stacker, the platform allows you to process polyimide, PET, FR4, paper, etc.

Industry 4.0

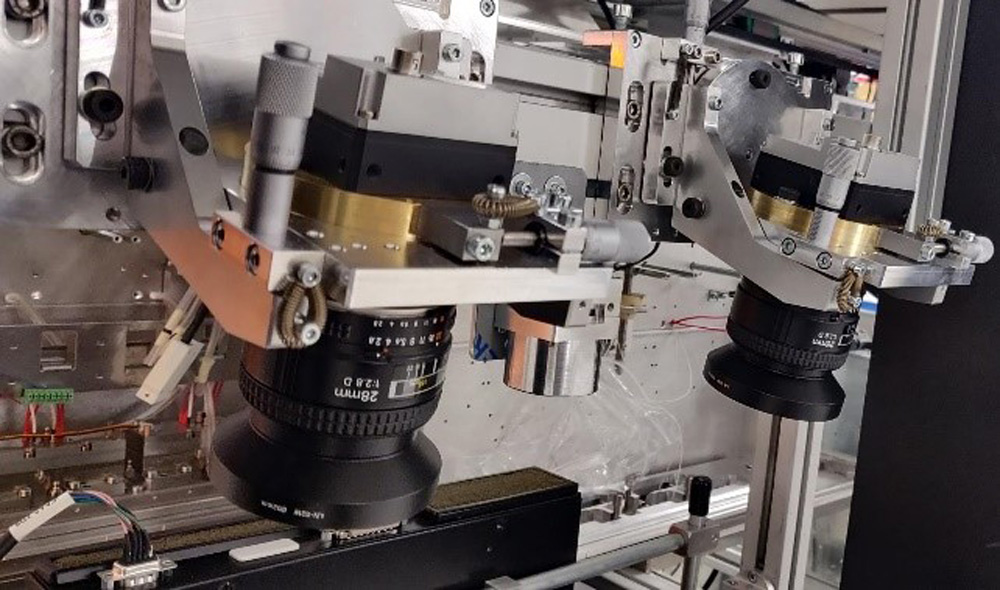

- Automatic inspection camera

- Image processing pipeline with user-configurable parameters to adapt to different components.

- Production serialization

- Import-export of production files and circuit status.