HFOne

Print your functional electronic inks

Achieve direct flex circuit printing on cost-effective substrates

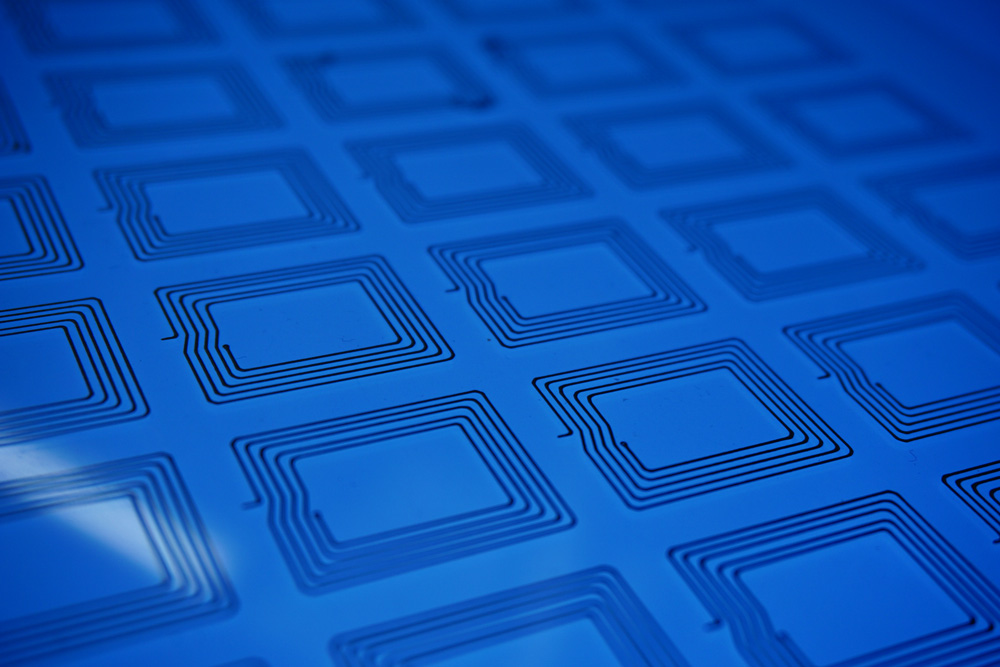

Accelerate your multilayer printed electronics production. After four years of R&D, the HFOne printer is ready for electronics manufacturers, for example, for RFID smart tags, IoTs or flexible interconnection systems with active components.

- Accelerate your mass production

- Reduce your time to market

- Adopt more environmentally friendly processes

- Reduce your production costs

A concentrate of technology

- Polymide

- Paper

- PET

A standard line prints 3 layers of functional inks in registered overlay.

A tracking and camera system controls the integrity of the functional layers.

Keep control of your productions

Monitor and control your Industry 4.0 factory using integrated cameras to:

- Real-time control of individual and assembled layers during production using KontrolVision+ image processing technology

- Print variable serialization data

- Qualify and trace your production with the serialization of each printed circuit board

- Visualize machine productivity in real time

- Export your information to the DPP320 R system for component assembly and automatic component programming

HF One: Beyond just a printer

Dare to take on new projects!

The HFOne can produce up to 1 million connected objects or antennas per day, while benefiting from a production process capable of handling batches of 5,000 to 10,000 circuits very quickly, thanks in particular to an ultra-short printer setup time.

Technical specification

Width of the web

33 cm

Print layers

1 to 3 print layers

Production speed

Up to 10m/min