PN series

Inkjet Printer for specialty applications

Does versatile and variable-thickness inkjet printers are key features?

In the industry, diversity of uses cases requires a scalable architecture with unique technologies. We believe the PN series matches such demand for printing, in exemple, on enveloppes empty or filled, on flat boxes for pharma, on pouches filled or empty, on cardboards, on paper…

Some exemple of specialty processes: printing watermark, printing MICR CMC7 inks for letter check, dynamic thickness compensation for mixed mail envelope printing.

Unique technologies for industrial printing

A small footprint print-tower fitted with a vacuum flat belt for moving document securely at high speed underneath the printheads.

A range of KEOS print slices with auto-thickness media compensation, auto-capping, auto-cleaning.

Real time RIP and variable data printing.

High resolution 1200 dpi, high-speed, in excess of 20 000 media/hour printed continuousely in 3 shifts.

A range of additional equipments for drying, print inspection and integrity check, communication capabilities with 3rd party equipment, additional processing modules.

Printers and modules range

Printers :

- PN300 up to 2 print slices max print width 30 cm, Monochrome

- PN302 up to 2 print slices max print width 12 cm, CMYK

- PN400 up to 4 print slices max print width 30 cm

- PN700 up to 4 print slices, max print width 100 cm

Modules :

- KAL100 Aligner, vacuum belt

- KAL100RFID +, RFID reader, programmer, integrity check

- VNODE300L, Line scan camera and Kontrol Vision read and print + inspection camera

- KONV 1, KONV2, Shingling conveyor 1 or 2 m

- KMS45, Vacuum belt, extension 45 cm for adding dryer or additional equipment

- BM1, Bypass unit for faulted or sorting

- KMF400, KMF500, Range of feeders for cardboard, envelopes, paper, boxes

Configurations

Simple stand-alone

Advanced

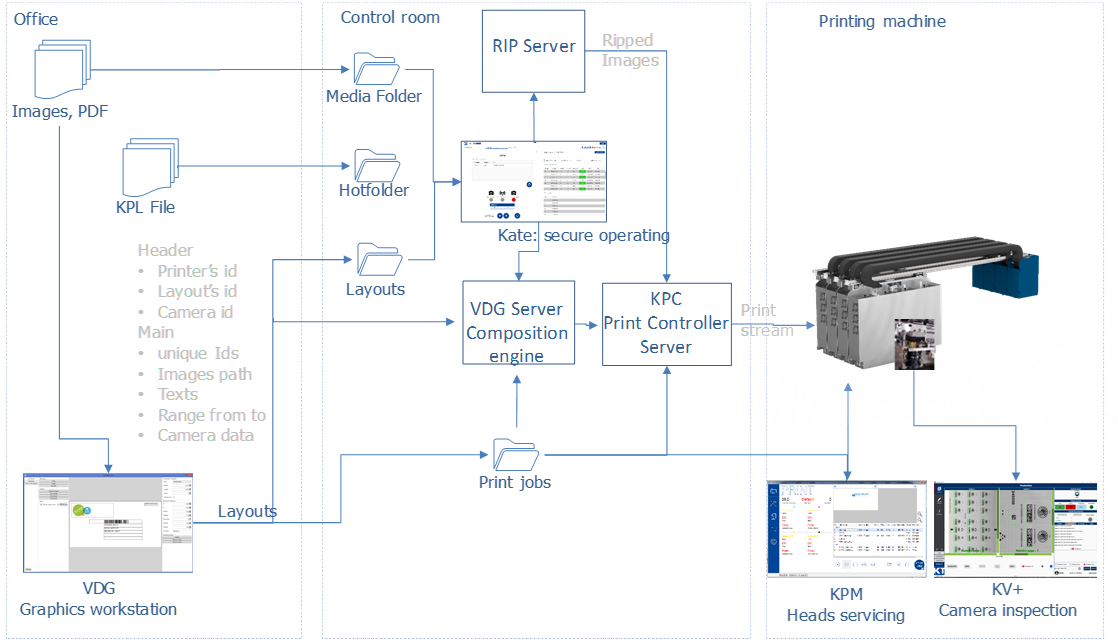

Software environment to operate inkjet printing

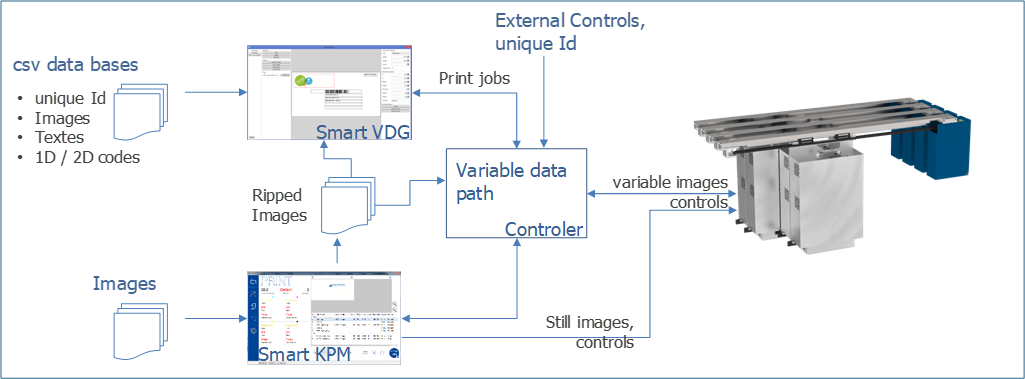

Smart KPM

Static print controller, print job selection, printer and production setup, status, maintenance

Smart VDG

Layout composer, variable data generator, variable data merge and job generator, monochrome or color, multi-pages

KRIP

BMP, TIF, JPEG, PDF, multi-pages, real time, CMYK, ICC profile, ink management

Kate

Secured operation, aggregator of software applications

KPC

Real time variable data print controller

KV+

Camera inspection, integrity control, auto print heads alignment and stitching, Delta E equalisation